Sustainable storage batteries are critical to successfully integrating renewables into the grid and powering off-grid buildings and microgrids.

Today, lead-acid and absorbent glass mat (AGM) batteries store energy from solar-powered schools and electric vehicles to cell phone towers, trains, and emergency room backup generators.

But how sustainable are they?

In this blog post, you'll learn:

- How moving toward zero battery waste helps your operations and the environment

- How to compare battery recycling rates

- Which batteries have a lower CO2 footprint

- Identify and weed out common causes of early battery failure

- How to select longer-lasting and more environmentally-friendly batteries

Financial and environmental benefits of moving toward Zero Battery Waste

Embracing zero waste in battery production protects the environment and saves money.

For instance, Crown Battery started comprehensive recycling and renewable energy programs decades ago. Building longer-lasting batteries (keep reading to see how) while reducing materials and manufacturing expenses translates into consumer savings – and enables Crown Battery to keep prices low.

Plus, zero-waste practices play a pivotal role in shrinking the environmental footprint of battery manufacturing.

Responsible manufacturing can be cost-effective and ecologically sound – especially when manufacturers rethink production from the ground up and ensure every stage, from R&D to recycling, aligns with sustainability goals.

And in battery making, sustainability starts with battery recycling.

Comparing battery recycling rates

Lead-acid and AGM batteries are 99% recycled – more than an aluminum can (source: U.S. EPA’s “Advancing Sustainable Materials Management: 2018 Fact Sheet”).

They’re continuously turned into new batteries, reducing raw material mining and other environmental impacts.

In contrast, only 5% of Lithium-ion batteries are recycled (source: Chemical & Engineering News, “It's time to get serious about recycling lithium-ion batteries”).

To learn more, including how the battery industry is working to close the Battery Recycling Gap, watch The Recycling Gap: Will Your Battery Recycle or Will You Pay the Disposal Bill?

Carbon footprints: How to select batteries with lower CO2 emissions

Lead-acid and AGM batteries, particularly those manufactured with renewable energy sources, have significantly lower CO2 emissions than other battery chemistries.

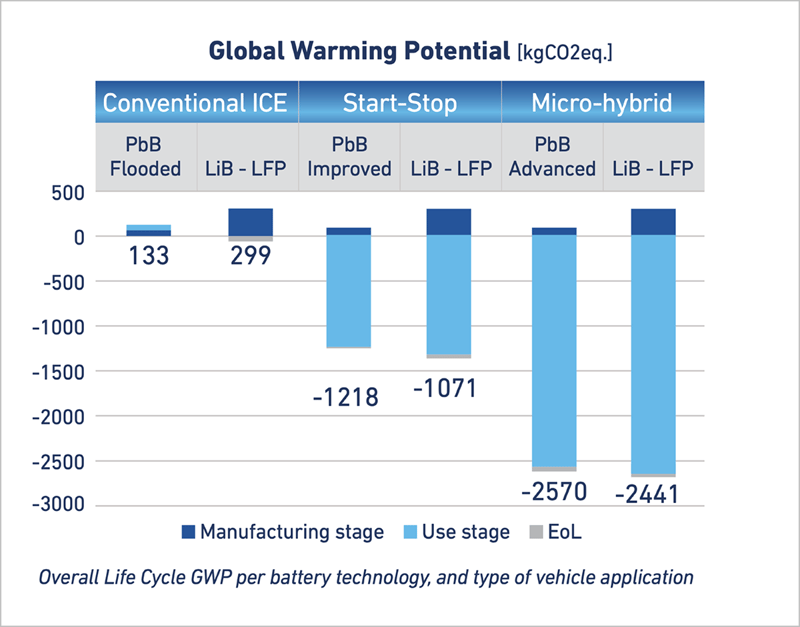

In September 2023, Sphera Solutions released a new study that compared the cradle-to-grave impact of lead-acid and AGM batteries versus Lithium-iron phosphate (LFP) models.

The independent report was commissioned by the Battery Council International (BCI) and the International Lead Association (ILA), following ISO 14040/44 standards.

Sphera Solutions’s lifecycle assessment evaluated everything from raw material extraction and processing to transportation, materials manufacturing, battery assembly, lifetime usage, and end-of-life.

After performing a complete lifecycle analyses of 12V lead-based and LFP batteries for automotive applications, Sphera’s researchers concluded:

- Lead-acid and AGM batteries’ global warming potential (GWP) is lower than Lithium-Iron Phosphate models

- Manufacturing burdens are 39%-90% lower for lead-based batteries

Source: https://batterycouncil.org/wp-content/uploads/2023/04/global-warming-potential_chart_1200x941.png

To learn more, read the “Comparative LCA of Lead and LFP Batteries for Automotive Applications” report here.

You can also lower CO2 emissions and replacement costs by improving battery longevity.

Identifying Common Battery Killers

When batteries last longer, you have to replace them less often. That’s good for your wallet and for the environment.

To extend battery life, avoid:

- Overcharging

- Deep discharging beyond manufacturer recommendations

- Exposure to extreme temperatures

- Undersizing batteries – which can lead to early failure and inadequate capacity

- Improper maintenance

Maintenance

Proper maintenance and usage are crucial to maximize lifespan and minimize operating costs.

To get the most out of your batteries in the shortest amount of time:

- Make getting started easier: Create a list of maintenance gear and tools, then store them in a convenient location.

- Document maintenance: Ask your battery and other equipment manufacturers for maintenance checklists - and display checklists where maintenance is performed.

- Schedule maintenance: Put it in your calendar or scheduling system.

Once you understand how to optimize storage, charging, and maintenance, you can mitigate common battery killers – and extend battery life.

Evaluating Battery Manufacturing Practices

Battery longevity and sustainability rely on minimizing mining and improving manufacturing.

And companies that invest in clean, efficient, and ethical manufacturing practices tend to produce more sustainable batteries.

For instance, Crown Battery:

- Builds new batteries with ~80% previously recycled materials

- Sources renewable energy for manufacturing

- Provides a 250+ point quality inspection

- Reduces scrap and improves reliability with robotic intercell welding, which allows for 3,960 more adjustments than conventional welding

- Publishes its waste-reduction strategies, recycling stats, and energy consumption

These practices ensure that batteries are not only high-performing but also environmentally responsible.

“People can say whatever they want over the phone and in sales pitches. But when I saw the Crown employees’ attention to detail, how clean the factory was, and the robotic assembly and computerized quality checks – we were sold.

Plus, Crown still makes all their batteries in America, and I like that. They’re an Ohio company, like us.”

– Jeremy White, General Parts Manager, Buckeye Power Sales

What’s Next:

If you want to lower your carbon footprint and boost your bottom line, download your free copy of Crown Battery’s "Zero Battery Waste Guide." This comprehensive resource outlines the roadmap for making sustainable battery choices and improving battery life and ROI.